FLOW OF PRODUCTION

01

Purchase・Drying

The material is bought in the competition city and dried in an artificial dryer for 2-3 months after 3-5 years of natural drying. After that, it takes another 2-6 months as a cooling period, and we take our time to finish it. This careful process supports the high quality of the product.

02

Transporting

After transporting top panel to the plant, rough cutting is performed to roughly match the application and size. Then rough cutting is performed to trim the surface. This process provides the foundation for the next processing step.

03

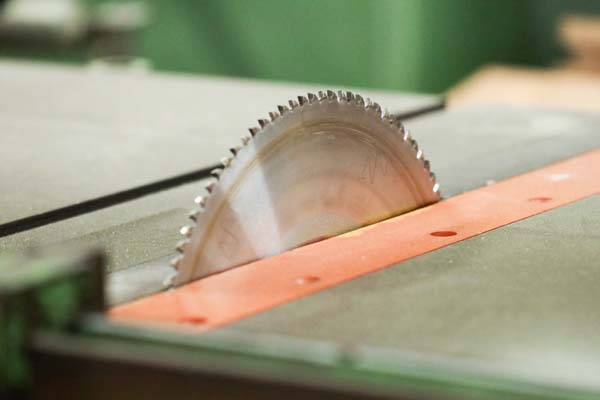

Middle shaving~Top panel cut

After smoothing the finish, the table is sized and top panel is cut precisely to fit the dimensions.

04

Repair

After cutting top panel, repair defective parts such as cracks and wood knot. This process is very important in order to improve the appearance and durability of the product and to maintain the quality of the product after completion.

05

Polishing

Carry out the first polishing of top panel and trim it. At this stage, the back side, sides, and ears are also polished as a basic work for finishing polishing, preparing for the next process.

06

Polishing

The second round of polishing carefully finishes the front, back and sides of top panel to create a smooth-to-touch feel. This process removes the fine irregularities of the wood and prepares it for the final finish.

07

Oil Coating

Oil is applied to the front, back, and sides of top panel to nourish the wood and bring out its beautiful luster. After application, a wiping process is performed to remove excess oil and ensure an even and smooth finish.

08

Polishing・Oil Coating

After grinding the back side of top panel and applying oil, repeat the process of finishing the front and sides in the same way twice. Through repeated painting and polishing, the oil penetrates into the interior of the wood, increasing its durability and gloss, and achieving a finish that retains its beauty for a long time.

09

Polish Top Panel・Wax Coating

The final step in top panel process is to carefully polish and then apply a wax coating. Through this process, wax protects the timber and draws out its natural feel and smooth hand.

10

Check・Pack

Finally, check the entire product and carefully check it for scratches and defects. After that, it is carefully packed and completed.